Nuvex Ingredients

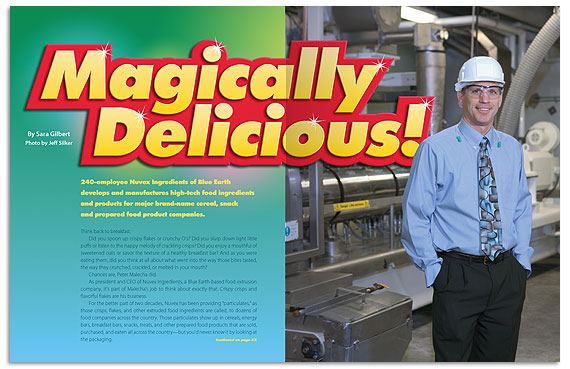

240-employee Nuvex Ingredients of Blue Earth develops and manufactures high-tech food ingredients and products for major brand-name cereal, snack and prepared food product companies.

Photo by Jeff Silker

Think back to breakfast.

Did you spoon up crispy flakes or crunchy O’s? Did you slurp down light little puffs or listen to the happy melody of crackling crisps? Did you enjoy a mouthful of sweetened oats or savor the texture of a healthy breakfast bar? And as you were eating them, did you think at all about what went into the way those bites tasted, the way they crunched, crackled, or melted in your mouth?

Chances are, Peter Malecha did.

As president and CEO of Nuvex Ingredients, a Blue Earth-based food extrusion company, it’s part of Malecha’s job to think about exactly that. Crispy crisps and flavorful flakes are his business.

For the better part of two decades, Nuvex has been providing “particulates,” as those crisps, flakes, and other extruded food ingredients are called, to dozens of food companies across the country. Those particulates show up in cereals, energy bars, breakfast bars, snacks, treats, and other prepared food products that are sold, purchased, and eaten all across the country—but you’d never know it by looking at the packaging.

“You will find our products in every major grocery store in America,” Malecha says. “We do breakfast cereals that are everywhere. But you’ll never see our name on the box.”

That’s not important to Malecha. What matters is that Nuvex can provide what its customers want when they want it. In an extremely small industry—Nuvex has only three or four legitimate competitors, all of which are owned by huge multinational food companies—it’s crucial to be capable of meeting needs immediately. And Nuvex, which places an enormous emphasis on research and development, prides itself on being able to do just that.

“Our clients know how they want the product to look and how they want it to perform,” Malecha says. “We know how to achieve that. And if we don’t, we’ll figure it out.“

Nuvex Ingredients was the brainchild of a young MBA student from Iowa State who decided in the mid 1980s that he wanted to feed the starving children of the Third World. With his idea and capital from local investors, he made a down payment on an extruder and developed product. That student set out to start a business in Algona, Iowa.

Six months later, the business, then known as Freedom Farms, was in financial trouble. But the idea of producing extruded food products was still valid, especially if marketed in a more conventional, for-profit manner. So the original investors got together, elected a chairman (Jon McClure, a longtime Iowa businessman), and raised enough cash to keep the idea alive. Then they went shopping for a new home.

It was purely happenstance that the company, then renamed Custom Food Processors, landed in Blue Earth. They were looking for something close to Algona, where most of the investors lived. They were looking for a community that would support the business and perhaps even offer it an incentive of sorts. And they found both in Blue Earth, a town of about 3,500 situated just 45 miles north of Algona that was willing to give the fledgling company six months free rent in a tin-sided building big enough to house the extruder they were waiting for.

Today, Nuvex Ingredients occupies 130,000 sq. ft. in a building in the same industrial park as the “shed,” as Malecha fondly refers to it now. The original extruder moved to the new building when it was built in 1991 and is still in operation, although seven other models have since joined it. The business now employs 240 people and is one of the top three employers in Blue Earth, just behind the school and the hospital.

Malecha joined those ranks in 1996, when McClure recruited him for the CFO position. He turned the job down twice before finally accepting it. A native of Faribault, Malecha had worked in far northern Minnesota before finding work further south—in Texas. Although his family had since relocated to Marshalltown, Iowa, they were all leery of moving north to Minnesota.

“My wife and I had agreed that we’d never move back to Minnesota,” he admits on a snowy January day. “We knew there was a warmer life. And when I brought my family up, they basically confirmed that we didn’t want to move here now.”

Still, Malecha couldn’t shake the feeling that Nuvex might be a good fit. He sensed that he and McClure shared the same values and the same passion for their work. “When I came here to interview, I felt like I made a connection with John McClure,” he remembers. “I felt like this was someplace that I could do some good.” But when McClure called with a job offer, Malecha turned it down. McClure, who had developed the same first impression of Malecha, called again some time later. Again Malecha said no.

“Then I came back here again,” he says. “I prayed about it. I knew that none of my family was keen on moving here—my daughter had just finished eighth grade and my son had just finished second grade. But when John called again, I said yes.”

That was in June 1996. Just more than a year later, he was asked to consider taking over the reins as president. This time, he didn’t need to be asked more than once. In October 1997, he became president of Nuvex Ingredients. “Originally, I thought I would come here, get a couple years of experience as a CFO and then move on,” he says. “But then they made me the offer and I changed my mind.”

Malecha’s tenure has been characterized by continued growth. The business has shown profit growth in each of the years he’s been there. It has expanded into new markets, patented new processes, and developed dozens of new products—including two created specifically for the low-carb craze (see sidebar, page 29). Malecha prefers to deflect responsibility for that success off his own shoulders and onto the rest of his employees.

“How does it happen? With good people,” he says. “It all starts with the people on the production floor, the people doing the manufacturing. We can hire sales people and marketing people, but if someone isn’t out there starting it up and making it run, we don’t have anything.”

Indeed. The company operates at least one and as many as six of its production lines 24 hours a day, seven days a week. Those lines must be staffed continuously by workers who pour hundreds of pounds of ingredients into giant blenders, then shepherd them through the extrusion, flaking, coating, drying, and packaging processes. Malecha makes it his business to try and know all of those employees—and to take care of them the best he can.

Shortly after he became president, for example, he implemented a significant cultural change. He began improving employee benefits and wages, a process that continues today. He received a state-funded grant to help implement a training program to help his employees do their jobs better. And he made a point of involving employees from all levels in important business decisions.

“The more involved you get the people who will be impacted by the decisions, the better decision you’ll make,” he says. “There are 180 degrees in every plane, and a possible 180 answers in every decision. And the more people you include, the better decisions you’ll make. Sure, it’s a time-consuming process. But in the end it’s shorter. It’s better to do it right the first time. It’s not always the easiest or quickest way, but it is the best way.”

In 2000, Ampersand Ventures, a Boston-based venture capital group, purchased Nuvex Ingredients. The move was necessary, Malecha says, because the original investors were looking for liquidity on their investment and because the business was ready to take another step in its growth.

“Ampersand brought us an infusion of new capital and new expertise,” Malecha says. Much of that capital went directly to additional research and development staff and to an increased sales force, as well as to another expansion of the facilities. He adds, “We need to diversify outside of the breakfast cereal market. We needed to grow the company.”

That enhanced sales and R&D staff got ahead of one of the biggest diet changes in recent history: the low-carb craze. In fact, the company had been paying attention to the importance of protein for years. “High protein diets were forerunners to the low carb diets,” Malecha says. “And we had been working with high-protein particulates early as 1998. We were already poised to take advantage of the changes coming about in the food industry.”

From 2003-2004, different U.S. companies introduced a total of 3,737 new low-carb food products in various forms nationally. As the craze hit, Nuvex was ready and waiting with the new ingredients its customers would be looking for. “We were ready for it,” he says. “In fact, we were ahead of it. We could react to it successfully. We were definitely able to ride that wave.”

But the company’s commitment to R&D hasn’t dissipated with the decline in Atkin’s dieters. In fact, as the general public has become educated about the importance of a healthy, balanced diet, demand for new food products will continue to grow. That’s why Malecha is especially proud of Nuvex’s pilot line—a scaled down extruder production line that allows researchers to continuously work with new ingredients to create new products. He estimates that they develop at least 100 new products each year. Although only a few of those will actually make it to market, he considers that money well spent.

“We have to be cutting edge,” he says. “We have to be constantly listening to the market, developing new products and solving our customers problems. That’s what we do. We’re a solutions-based company.”

The next horizon for Nuvex is to grow through strategic acquisitions. With the help of Ampersand, Malecha is looking for companies that can compliment what Nuvex already does well. “We’re trying to find companies to add to Nuvex that will make us a better company,” he says. “We’re looking for more product diversity and more customer diversity. We make healthy food, and we want to align ourselves with other companies that make better-for-you products.”

And although you may never know it, you may be eating those products for breakfast (or even lunch or dinner) someday soon.

Keeping Secrets

When a visitor or new customer comes to visit Peter Malecha at the Nuvex Ingredients plant in Blue Earth, they often get to put on hairnet, a hard hat and take a tour of the facility. But there are often certain things they don’t get to see while they’re out and about.

“We can never allow one customer to see someone else’s product being made,” Malecha, the president and CEO of the food extrusion company, says. “There’s a lot of secrecy.”

He can mention the reputable companies who are clients, but he can’t do much more than drop their names. “Take Kellogg’s,” he says. “They’ve said that I can say that we do business with them—but I can’t say what business we do.”

Such secrecy extends to the research and development lab, located at the far back of the building. It has a separate entrance, a separate parking area, and a locked door that leads out to the production area.

“It’s very important for us to safeguard the technical aspects of what we do,” Malecha says. “That’s why this is so separate, with its own bay and its own entrance.”

Counting Carbs

The low-carb craze could have been catastrophic for Nuvex Ingredients, a company that had basically made its business creating carbohydrates. But it wasn’t.

“We were ready for it,” says Peter Malecha, president and CEO of Nuvex. “In fact, that craze really gave us an opportunity to show how good we are at developing and manufacturing different ingredients.”

Nuvex’s R&D department took the opportunity to develop many new products that for the most part displace carbohydrates with proteins. Two of the most successful are Net Zero Carb Crisp and Proti-Oats, a low-carb rolled-oats replacement. Nuvex is patenting both.

Although the low-carb wave seems to have crested, Malecha is sure those products will continue to be mainstays in a more carb-conscious marketplace. “There was a huge spike in new products in 2004, but I think that sort of growth is short lived,” he says. “Still, I think that low and managed-carb diets will always be popular. I don’t ever see it going away.”

Out Of The Woods

Peter Malecha started his adult life as a forestry technician. His first job was in Blackduck, Minn., where he took his new wife with him to work with the Department of Natural Resources. But by the time their fourth year there was over, they both knew it was time for a change.

“That year was my first brush with consensus management,” he remembers. He spent a year in meetings, working with several colleagues to come up with a comprehensive plan for how the DNR might better certify different levels of forestry technicians. That process, and his taste of “business,” was all it took to change his career path.

“My wife and I did a lot of soul searching and decided that the right thing was for me to go back to school,” he says. “I had talked to a lot of the contacts I had made over the years, and all of them said that if I wanted to get into business, I should get my degree in accounting.”

So Malecha enrolled at Bemidji State. He spent the next three years studying all week and working all weekend. When he finished, he landed his first job with Fisher Controls. For the next eight years, he worked in various financial positions. And then he got the call from Jon McClure about the CFO position at Nuvex Ingredients.

Looking back, Malecha says he’s glad he took the chance to find out what he was really meant to do. Although he loves the outdoors, he knows that his future wasn’t meant to be in forestry. “We’re all given different gifts at different levels,” he says. “We need to figure out what those gifts are—and we need to not let ourselves be dissatisfied with what we do because we’re unwilling to change. We have to be willing to change.”

© 2005 Connect Business Magazine. All Rights Reserved.