Tom Engdahl

Photo by Jeff Silker

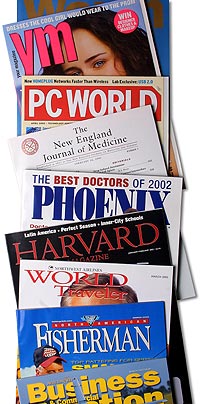

Brown Printing COO Tom Engdahl didn’t bring along to seat 7D his latest New England Journal of Medicine with the article on “Pulmonary Langerhans’-cell histiocytosis” – or for that matter, any other publication his company prints.

At this instant he’s on another late-night Northwest flight to Germany, his umpteenth this past year, and he’s stuck next to a Russian babbling on about Ukrainian social customs. Engdahl begins shuffling through the in-flight magazine. He departed Minneapolis at 9:00 P.M., he’ll skid into Frankfurt at 12:10 P.M. – the mother of all jet lags – and have a three-hour layover in which he’ll likely get a crick in his neck from gazing up at another CNN monitor before flying KLM on to Hamburg – arrival 4:50 P.M. It’s home for Gruner + Jahr, the $4 billion parent of his company.

Engdahl, 53, was named Chief Operating Officer of Waseca’s Brown Printing a year ago, in effect becoming the pilot of a 2,700–employee, $380–million jumbo jetliner that prints hundreds of the nation’s finest business and trade journals, and magazines. The magazine printing industry began a steep dive into a recession, er, depression in the exact same month Engdahl began flying solo at Brown, March 2001 – simply bad timing. But that’s nearly behind him. Right now he’s thinking about pleasant things.

Hamburg’s Steigenberger Hotel serves the local favorite, matjes, a raw, pickled herring, but Engdahl’s thinking tonight he’ll order labstaus with fried potatoes. He’s been at the Steigenberger so much he thinks the desk clerk knows his wife’s name. At dinner he’ll try fiddling over colorful copies of Stern and Die Welt, but since he doesn’t know the language it might as well be Greek. And so goes another overseas trip (and a partly fictional one) for an American executive working the global village.

CONNECT: Brown Printing Company is the nation’s fifth largest publication printer?

ENGDAHL: Yes, and in the trade and business publications category, which makes up about 48 percent of our total business, we are the nation’s second largest. We have annual sales of $380 million, about 2,700 employees, and printing locations in Waseca (which includes the headquarters), Woodstock, Ill., and East Greenville, Penn.

We are a wholly owned subsidiary of a German company, $4 billion Gruner + Jahr, which in turn is more than 70 percent owned by Bertelsmann AG, an $18 billion media giant based in Germany. Bertelsmann AG also owns Random House, the largest English-language book publisher in the world, and BMG, Arista, and RCA music labels.

Gruner + Jahr is the largest magazine publisher in Europe and its U.S. publishing division, Gruner + Jahr USA, publishes Family Circle, Rosie, YM, Parents, and Fast Company among others. The U.S. division, our sister company, is the nation’s fifth largest publisher. In short, they publish and we print.

CONNECT: You are personally responsible for three facilities then, in Minnesota, Illinois and Pennsylvania. How does the business break down among those three?

ENGDAHL: The Waseca plant represents about 45 percent of our total volume, and then Illinois and Pennsylvania split the remaining. The plant in Waseca is the largest, and it’s the founding division. “Bumps” Brown founded Brown Printing. His father had owned the newspaper in Waseca, and when Bumps returned from World War II, he went into business with his dad. When the press wasn’t running newspapers, they used the down time to run flyers, and this side business grew in 1957 to be a printing business in and of itself. Bumps sold the business in the late ‘60s to Minneapolis-based Bemis Corp. In the late 1970s, Brown built the East Greenville plant and a rotogravure printing division in Kentucky.

Executives at Brown, in an effort to better understand the rotogravure printing process, had gone to Germany where the highest concentration of rotogravure expertise is located. There, they met up with Gruner + Jahr, and from that meeting established a connection that would lead to the eventual sale in 1979 of Brown from Bemis to Gruner + Jahr.

Gruner + Jahr isn’t a seller, but a buyer and builder of companies. It is a stable parent and financially strong. Since Gruner + Jahr and Bertelsmann AG are both so solid financially, we’ve never had to look over our shoulder here to wonder if they are having financial troubles or using us as a cash cow to fund other projects. Here, we’ve always been able to just focus on what we are doing. When we’ve needed capital for growth or reinvestment — and we’ve made our case — we’ve been rewarded.

CONNECT: How often do you fly to Germany?

ENGDAHL: In the past year I was there eight times. It has been an unusual time in our industry because of the tough economy, and that has created more concern about the state of business. In addition to all that, I’m relatively new in my position and need to see my “boss” in Germany more often than an established person in my position would.

CONNECT: Effective January 1, 2001, you were promoted to Chief Operating Officer and assumed the duties of Dan Nitz, former CEO. What kinds of pressures do you face in taking over a $380 million company from a man who had been CEO here 12 years, and had been in the company itself for 20?

ENGDAHL: Of course I feel pressure. (Laughter.) It’s a wonderful opportunity here for me, though. What helped is that I have known Dan since 1973 when I worked with Procter & Gamble. Dan was the one who recruited me to Brown Printing in 1984 when Brown was looking for more management horsepower. In addition, although Dan left, the rest of the leadership team did not. And, that’s an extremely experienced, talented, and effective team I’m fortunate to be part of.

But, Dan’s shoes are big to fill because he did a terrific job. Another factor that has caused pressure is the fact I came on board at the exact same time the economy began falling off a cliff. For the last year at Brown we have been preoccupied with managing our way through this recession, which in effect has been a depression for the advertising industry, and as such we’ve been having to deal with much lower volume. When there are fewer advertisers in magazines, the magazines have fewer pages, which in turn directly affects our business.

Our business is one of volume. While our press volume is down, our binderies haven’t been hurt too much because the number of “books” (magazines) we print is about the same as before the recession, it’s just that the books are smaller.

On top of that, there has been an increase in competition for work among the printers. So everyone in the market is fighting to maintain their profits. Even though Brown Printing is still profitable, and a strong company, there are people here working less hours because of the lower volume, and that means less income for our employees. Their situation has been a real concern of mine.

CONNECT: Dan Nitz trained you for two months before he left. What did you two do to make the transition easier?

ENGDAHL: Basically, we went on a “nationwide tour” to introduce me to all the major customers I wasn’t familiar with. Internally, I had been here a number of years already, and knew many of the people, which meant I didn’t have the difficulty an outsider would have had initially getting on board.

CONNECT: When you traveled the country those two months, my guess is the actual meetings lasted only an hour or so. That left you and Dan with a lot of free time. What did you and he talk about in the taxi, on the airplane, and in the subways?

ENGDAHL: We spent a lot of time talking over the next six months in terms of major issues and strategies for approaching contracts. We talked over major capital projects that we needed to persuade our owners to support.

CONNECT: You worked for Procter & Gamble 11 years. That company is known for its aggressive marketing. What did you learn from them?

ENGDAHL: I learned a lot, but nothing about marketing. (Laughter.) Procter & Gamble, being committed as it is to promoting from within, spends an incredible amount of money and time training new managers. Coming out of college, my joining P&G was like enrolling in a management school. In those 11 years I had the opportunity to attend 20-30 different skill-building or educational events, and at the same time I had six different assignments, including positions in engineering, human relations, and three levels of manufacturing management. P&G was a tremendous training ground for building managerial skills, leadership skills, and for gaining experience.

CONNECT: With Brown, you were a division general manager before being promoted to Midwest Region Vice President of Sales in 1997. From engineering to manufacturing to sales must have been a big change.

ENGDAHL: Yes, it was. What helped most is the team of sales reps in my group were all highly successful professionals. Also, what helped was spending those seven years as division general manager in Kentucky; and in that role I interfaced with customers and shouldered some responsibility for sales and pricing decisions. I had a good deal of experience negotiating with customers going in, and my sales experience just gave me a much heavier dose of it. Plus, and more importantly, I had the opportunity to look at the organization from the vantage point of a sales manager instead of as a manufacturer. It was valuable experience.

CONNECT: Your top publications printed in Waseca?

ENGDAHL: We print a couple hundred titles here, and many of those, as I’ve already pointed out, are monthly trade and business publications. We print a few weekly or biweekly publications, such as New England Journal of Medicine, which we have printed for more than 25 years. Many of our clients have been with us 25-30 years, and they form the core of our business. We take print orders starting at about 30,000 and the average for a magazine is about 130,000 copies. Our largest monthly order, one for 2.5 million copies, is filled for our parent company, Gruner + Jahr, for YM magazine.

CONNECT: Keeping up with technology must be at the very heart of your business. Could you explain some recent technological advances such as “computer-to-plate” printing and “closed loop color.”

ENGDAHL: Film is rapidly being eliminated from the publication process. We are receiving our information now from customers in digital format; with some sending data over the Internet and others on disk. We use a “computer-to-plate” process that eventually gives us a printing plate made directly from the digital page data. In the past we would have to take film and mount it, and use devices to scan the film and convert it to plate exposure.

We have installed “closed loop color” systems on a number of presses. The system automatically adjusts the ink keys on the press after reading the color bars, and this allows for more consistent color throughout the run. It requires less staffing because we don’t need a person there constantly to visually look at the pages and manually make adjustments.

We have adopted other technological advances, particularly in using automation at the end of the production line. We have robotics that automatically take signatures (the raw printed material before binding) off the press and put the signatures onto skids. We need operators for the robots yet, but no longer do people need to lift by hand. In the bindery, we have “hopper” loaders on our equipment, which allows us to fill the pockets on the saddle stitchers and perfect binders with more signatures, and there again, with that, we reduce labor costs.

CONNECT: It’s one issue to adopt new equipment and it’s another issue to train employees in how to run them. How much of an issue is training?

ENGDAHL: It’s very important, but no more so than in any other industry that is converting from low- to high-technology. If you were to visit one of our presses today, you might say that the operator’s panel looks like something you would find on the space shuttle. In our plant, people not only need to learn how to push all the right buttons, but they also have to know what happens after they push the buttons. It requires a great deal of technical training, so systems must be in place to make sure these people have it.

CONNECT: In November 2000, Brown Printing in Waseca received a three-year, $350,000 grant from the Minnesota Job Skills Partnership to use in partnership with South Central Technical College. Its purpose was to retrain pre-press department employees in digital technology and to upgrade the communication skills of manufacturing employees and supervisors.

ENGDAHL: I do know that people here feel good about the program. Through it we have been able to bring people in, and train them, and retain them. We’re always looking for more people for our operation even during this slow economic period. We’re never so full that we stop looking for good people, especially in entry-level positions.

CONNECT: The events of September 11 affected you in more ways than one. Last September 11, the U.S. Postal Service, on the same day as the World Trade Center attack, decided to raise postal rates to make up for losses in volume, primarily due to email. I would guess that the mailing side of your business is sometimes just as important as the actual printing. How do higher postal rates affect you?

ENGDAHL: The postal service is always raising rates. It’s of great concern to our clients because as much as one-third of the cost of publishing a magazine is eaten up in distribution, which includes postage and freight. We take advantage of postal discounts for delivering mail directly to sectional postal centers rather than to the local post office. Each magazine has its own distribution plan, and it varies according to the circulation and weight. We also pool magazines to reduce freight costs.

Rising postal rates hurt our clients. For those on the edge, a small rise in rates could be the extra push that causes them to cease publication. Another concern for us is that as postage rates rise, magazines will become less competitive with other media. Advertisers have other places to spend their dollars, e.g., television, radio, Internet, billboard. When postage rates rise, magazines might be forced to raise their advertising rates, which in turn could make them less attractive to advertisers.

CONNECT: Hundreds of magazines are published in New York City. Were any of your customers directly affected by September 11?

ENGDAHL: Directly affected in the sense they were located in the World Trade Center area? — no. Most magazine publishers are in midtown Manhattan — and that’s where ours are. There were people we knew who were personally affected.

CONNECT: I’ve heard people talk about the eventual demise of all print media because of the Internet. Are on-line publications stealing business from you?

ENGDAHL: Over the last few years we have spent hundreds of millions of dollars in reinvestment to increase our production capacity. Implicit in that statement is your answer. We don’t believe there will be an erosion of the magazine industry anytime soon because of the Internet. Brown Printing Company has been a very successful business for more than 40 years, and we expect it to continue on in that vein for many more years. Our Waseca workforce is knowledgeable and committed, and they have a culture of quality that is helping us maintain our competitive position in the industry.

CONNECT: Why your involvement with Technology Plus, the business incubator in Mankato?

ENGDAHL: We have a long-standing relationship with Minnesota State University and its computer science interns, who, by working for us in Mankato at Technology Plus, avoid the 25-mile commute to Waseca. As a result, our linkage with Technology Plus has helped us recruit top-caliber MSU computer science students, which, in turn, keeps top-rate talent in this region. Our student interns dial-up to us from Mankato. Right now they’re working on significant software development projects. It helps them gain industry experience, and even if they don’t stay on with Brown after graduation, the experience still enhances their value in the marketplace. Technology Plus helps provide meaningful internship opportunities for MSU students; it helps us with real development projects; and it helps Technology Plus. Our human resources vice president, Harry Popiel, is a Technology Plus board member.

CONNECT: I noticed a Carlson Craft catalog on your lobby rack. Do you print for Taylor Corp.?

ENGDAHL: Sure. We are very fortunate to print some of Taylor Corp.’s longer-run catalogs. Our companies really don’t overlap from a product standpoint. Our niche is high-volume magazine and catalog printing. Of our total business, twenty percent of our volume is catalog and commercial work and it’s an extremely important product line for us. Catalogs and magazines complement each other. We have a tremendous amount of capital invested in our presses and binders, and it’s all fixed cost. If you don’t run them 24/7, you’re simply not going to make money — money we need to reinvest in the business. Our magazine and catalog publishers put us on strict schedules; but together they complement rather than distract from each other.

CONNECT: Would a Highway 14 bypass help your business?

ENGDAHL: We move 30-50 trucks in and out of Waseca every day. We’re pushing for the upgrade of U.S. Highway 14 to a four-lane expressway, primarily from a safety and quality of life issue. That highway is dangerous and our Brown employees drive it every day. We are highly concerned about it. On the other hand, no, it’s not choking off our operation to the point we’re not able to remain competitive in our industry.

CONNECT: Brown Printing has a tradition of the top person staying on for a long time. You’re only the fourth president in more than 40 years. Is it your intent to stay?

ENGDAHL: Oh, yes! I would like to be here for at least the next ten years, and to continue the tradition.

The Big Jobs

While Brown does print hundreds of little-known magazines, business journals and trade journals bearing titles such as Underground Wine Journal and Biblical Archaeology Review, the bulk of its business comes from larger clients:

Minnesota Monthly

Mpls/St Paul

Twin Cities Business Monthly

New England Journal of Medicine

American Family Physician

Departures (American Express)

Interior Design

Essence

Child

YM

Mayo Health Letter

PC World

Tom Engdahl Biography

Chief Operating Officer since January 1, 2001.

Born: March 19, 1949.

Education: Lake Forest High School, Lake Forest, Illinois ‘67; B.S. and M.S., Univ. of Michigan, in Industrial and Operational Engineering.

Personal: wife, Cindy; daughter, Claire, 10.

Memberships: Former board member, Gravure Association of America.

© 2002 Connect Business Magazine. All Rights Reserved.Tom Engdahl