Fly Away AgriProducts Inc.

Photo By Jeff Silker

Boo-hoo, said the businessman because he couldn’t find enough qualified workers to help him make his product line. The labor shortage in Minnesota had inflated his wage costs and cut his margins to the bone in a dog-eat-dog industry. What was he going to do?

When Duane Sibbet was hit with the above quandary, he didn’t boo-hoo. Rather he did what he thought made sense: he closed up shop. And close he did – his Twin Cities home construction business – and began a whole new career and business at age 40 in Blue Earth, Minn., compliments of that city’s economic development authority and an idea gleaned from his parents’ horse blanket business.

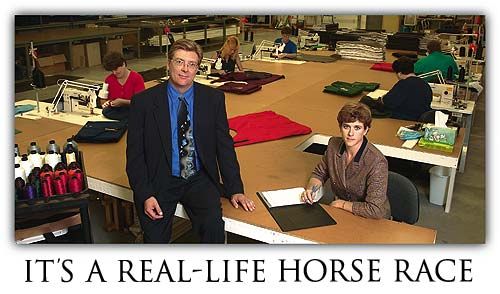

He began Fly Away AgriProducts Inc. in the dining room of his Jordan, Minn., home in 1997, designing and manufacturing screens for horse barn doors. To take his fledgling business to the next level he needed help, so he contacted Community Venture Network, an association of economic development directors representing communities outside the seven-county metro area. (The Network assisted entrepreneurs such as Sibbet who were willing to relocate from metro to outstate.) Through it he was wooed by sixteen different cities. He chose Blue Earth because of its generous financial package and, most importantly, its city-owned building that matched his production needs to a tee.

“I was really sold on the building,” says Sibbet, 43 now, a man whose pent-up energy rumbles beneath the surface, much like a revved chainsaw before it cuts firewood. “It was a new, vacant building that had extra space for growth,” he adds, “and since we were in the sewing business, we needed a very clean environment, too.” All the other communities courting him had facilities that required extensive remodeling. Of course, the economic development authority’s financial package, including its seed money, also were instrumental in his decision. Emboldened, he moved his business from Jordan to Blue Earth “compliments of the economic development authority” and began manufacturing there on September 27, 1998.

Up until then he had been a carpenter, a framing subcontractor, and finally a general contractor building homes under the name Duane Sibbet & Associates in Jordan. “It was a very difficult, competitive industry, very difficult to make a living against the corporate builders,” he laments. “I was underfinanced; each day was a new challenge.”

The labor shortage was his No. 1 enemy, though. “It was the primary reason why I’m here and doing this now,” he claims. “In the strong Twin Cities economy it was extremely difficult to find qualified help and to schedule building projects with any degree of certainty. If another contractor was doing a project, and could pay its laborers a little more, my workers would go to them.”

Labor shortages, he says, haven’t been a problem in Blue Earth where a Help Wanted ad can fetch up to 30 responses. (A recent one he placed for administrative assistant received 20.) Beyond the immediate labor pool of Blue Earth and its 3,800 citizens, he is also counting on the populations of Mankato and Albert Lea, both 40 miles away, and Fairmont, 20 miles off, for future employees. It has been easy to attract candidates because, unlike work in the construction industry, his brand spanking new facility is “clean, warm in the winter and cool in the summer.” He says the move to Blue Earth was certainly the “brightest” decision he could have taken.

The idea that started his business and career change arose from his lifelong exposure to his parents’ horse blanket business. He would manufacture screens for horse barn doors that would keep the “flies away.”

Sibbet credits much of his success to the “stick-to-it-tiveness” he learned from his parents, particularly his mother, whose work ethic has always been “fabulous.” She was like a postage stamp, he says, sticking to her work until she got it done. It was an excellent education in entrepreneurship. He would have kept at the family business had he and his three brothers strong personalities not clashed. (Of the four, only the youngest stayed on at “RaDon.”)

His father began the family horse blanket business in the mid-60s, with his mother cutting cloth by hand and sewing the blankets in the basement of their New Prague home. Hence, Duane was raised up in the sewing business from early on – and also around all the many horses that his parents and family friends owned. (Today RaDon, still run by Sibbet’s 76-year-old mother, has 15 employees and ships horse blankets the world over.)

After cashing in his “fluctuating” homebuilding business in 1997, Duane knew for a fact he “wanted to be in an industry that really isn’t affected by fluctuations in the economy.” Horse people tended to be upper-income, with plenty of disposable income, and since he understood the horse industry as well, a transition into it seemed the logical move.

“I came up with the idea for the screen doors,” he says. “My father was a horse farmer, and we’d visit stables. As a little boy I’d see these screen doors on barns, which were constructed with a wood frame and aluminum screen. Eventually they would all fail under their own weight. Later, because of my carpentry background, I figured out it was the frame that caused them to fail.”

So he began in his Jordan dining room, designing frameless screen doors for large 12′ x 12′ horse barn doors. What he eventually developed was a very strong curtain that doesn’t sag, made of high-tensile polyester and a flexible PVC coating. His curtains were better because they could be easily fitted onto older, hinged wood doors. To put in the traditional wood frame and aluminum system, older doors had to be removed first, which cost time and money.

Then he sought out the Community Venture Network to expand, and since his dream was to enter the equine market – what he knew best – he was overjoyed when the City of Blue Earth offered him seed money and a clean, vacant building near I-90. All of which seems like an American success story in the making, just another typical Connect Business Magazine feature, except for the fact that he really hasn’t built up a solid reputation yet in the equine market. His success thus far has come almost solely from an unexpected, even udderly amazing product: the calf jacket.

Milks Profits From Bovines

“Our calf jackets for newborn dairy cows now account for 65 percent of our business, which amazes us,” says Sibbet, reflecting a bit on all his knowledge of the horse industry before continuing on about cows. He has been a quick study in bovine issues, from calf health to management. “The product has acceptance in the industry. Several scientific studies have documented how cold affects newborn calves. A calf has a very weak immune system until about four weeks old. Until then they are typically segregated and put upwind to help withstand pathogens until their immune systems are developed.”

By using a calf jacket, dairy farmers can grow their calves up to an extra 54 percent the first 28 days, and with up to 52 percent more internal insulation in “brown” fat. All this is important, Sibbet says, because a shortage of heifers has developed in the milking industry, a shortage that wasn’t apparent just five years ago. His calf jackets began selling because it was “very cost-effective and machine washable,” he says. “Machine washable means there aren’t any cross contamination issues from calf to calf.”

He stumbled onto the business while exhibiting screen doors at the 1997 World Dairy Expo in Madison, Wisconsin. A New Zealand company, the only one in the calf jacket market then, was selling jackets made of wool, which meant they couldn’t be rewashed. He instantly realized he could make a better blanket, and later did, from the same materials used by his mother to fill horse blankets. Thinsulate, a product used in hundreds of products worldwide, doesn’t fall apart in a washing machine like “hollow fill” does, and won’t absorb moisture like “open-cell foam.” At the time he thought they could sell maybe a few hundred jackets a year, be done with it, and make it into a decent winter line to balance out the summer seasonal sales of screen doors. (Flies are only a problem in the summer.)

“We didn’t realize we would be selling thousands and thousands,” he says, shrugging his shoulders in disbelief. “Last year alone we manufactured about 15,000. It was almost an accident the way it happened. Of course, at the time I didn’t realize the product’s potential.”

A Fly Away AgriProducts calf jacket retails for $55. Most are marketed through a worldwide distribution network that stretches from Japan to Egypt. (Three thousand were shipped to Japan alone last year.) Dairy farmers in the southern U.S. have been a good source of sales, buying the jackets to take the bite out of the damp southern cold. Their “unexpected” product, the calf jacket, has turned what was a summer seasonal company into a winter one. Company sales in 2000 are projected to reach over $800,000, nearly doubling from 1999.

Staying On The Horse Trail

Even though his bovine products have sold like hotcakes, don’t expect Sibbet to focus on them and give up on his dream to expand into the equine industry. You have to believe him when he says with all forcefulness, “Our primary markets are going to be equine.”

Most recently Fly Away AgriProducts was a corporate sponsor of the Quarter Horse Congress, held this year at the Ohio State Fairgrounds. It was the world’s largest horse show and sixth largest convention of any type, covering a 25-day span. Sibbet earned his corporate sponsorship by donating 600 linear feet of horse screen that will become the walls of what is normally a wall-less roofed riding arena. Each screen panel is 15′ x 25′. The screen not only keeps out flies, but also lessens the impact of sun, rain and wind on the riding area, creating a more pleasant experience for both rider and spectator.

An American Horse Council study convinced him of his product’s potential. “Most people don’t realize the horse industry is directly responsible for $36 billion in spending annually, and indirectly, $112 billion,” he says. “It’s larger than either the railroad, tobacco, airlines, or motion picture industries – and this is just the U.S. equine industry. Certainly there is a strong equine market in Europe, Brazil, Australia, South Africa, and South America.”

The industry is so enormous that he claims he could make a living selling but one of his Fly Away products – the screens for riding arenas (such as the one at the Ohio State Fairgrounds) – just to accounts in southern Oklahoma and northern Texas. “In fact,” he adds, “we could probably make a very nice living selling just to accounts in Denton County, Texas.”

From the equine industry, the bulk of their sales contacts originate from trade shows and advertising placed in trade journals and magazines, such as Quarter Horse Journal and The Horse, a horse health magazine. They are choosy in placing magazine ads because of the cost, but feel the repetitive exposure is needed to give their one-of-a-kind product credibility with their target audience. The seasonality of sales to the equine industry can be tempered by selling to accounts in the southern hemisphere, such as in South America, Australia, and South Africa, where January is midsummer (fly season), and July midwinter.

They take their business on the road. “In essence, our retail ‘store’ is where we are on any given day,” he says. “We just had a ‘store’ in Calgary, Alberta, for six days, and then it flew back to Blue Earth. We will have a store in Columbus, Ohio, at the next trade show. Our ‘store’ is the next show.” Trade shows are important because customers feel a need to touch their product’s fabric, and see it for themselves. It’s that new of an idea. While Sibbet flies away on his regular jaunts to trade shows, Alex Sucher, his Director of Operations, along with all his “wonderful people,” hold down the fort quite nicely.

Besides calf jackets and horse barn screens, the company also manufactures vinyl doors for milking parlors, trail packs for trail bike riders, hay bags and horn bags for horses, and a turkey trailer containment system, which cuts down on litter and the spread of pathogens. Another unique product, manufactured for Featherlite, is a trailer screen for drop-down feed doors in horse trailers, which won an award at Equitana USA, a major Kentucky horse show. The company also won another award for its screen doors at Equitana USA, and an award at Equi-Fair, Canada’s largest horse show. The awards, doled out by top horse industry professionals, lend credibility to their product line, which in turn leads to improved sales.

Patent Yes, Patent No?

What hasn’t he sought patents for his products?

He says, “I had to answer my own question: Was it really worth spending all that money patenting a product when a patent may not protect me anyway? I struggled with that issue. With limited resources does it make sense to tie up money with a patent when that money could go a lot further in building the business? The money could buy sewing machines and inventory, which are more important to us now. We have to be wise about using our funds.”

“If somebody came in and stole our idea I would welcome it. We’re trend setters. If we had another competitor we would have greater market acceptance, and I’m certain it would boost our sales,” Sibbet says.

© 2001 Connect Business Magazine. All Rights Reserved.