Canyon Outback

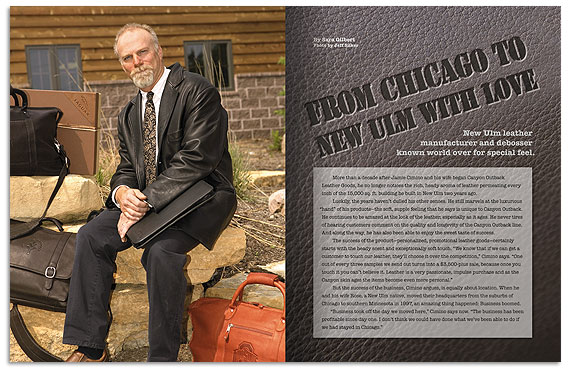

New Ulm leather manufacturer and debosser known world over for special feel.

Photo by Kris Kathmann

More than a decade after Jamie Cimino and his wife began Canyon Outback Leather Goods, he no longer notices the rich, heady aroma of leather permeating every inch of the 15,000 sq. ft. building he built in New Ulm two years ago.

Luckily, the years haven’t dulled his other senses.

He still marvels at the luxurious “hand” of his products—the soft, supple feeling that he says is unique to Canyon Outback. He continues to be amazed at the look of the leather, especially as it ages. He never tires of hearing customers comment on the quality and longevity of the Canyon Outback line. And along the way, he has also been able to enjoy the sweet taste of success.

The success of the product—personalized, promotional leather goods—certainly starts with the heady scent and exceptionally soft touch. “We know that if we can get a customer to touch our leather, they’ll choose it over the competition,” Cimino says. “One out of every three samples we send out turns into a $3,500-plus sale, because once you touch it you can’t believe it. Leather is a very passionate, impulse purchase and as the Canyon skin ages the items become even more personal.”

But the success of the business, Cimino argues, is equally about location. When he and his wife Rose, a New Ulm native, moved their headquarters from the suburbs of Chicago to southern Minnesota in 1997, an amazing thing happened: Business boomed.

“Business took off the day we moved here,” Cimino says now. “The business has been profitable since day one. I don’t think we could have done what we’ve been able to do if we had stayed in Chicago.”

Import-ant Beginnings

Jamie and Rose Cimino met in Mankato, where they were both attending Minnesota State University. Jamie moved back to his hometown of Wheaton, Illinois; Rose followed when the couple was married in 1983. Always an entrepreneur, Jamie was eager to start a business—and had decided that importing was the best opportunity.

“We wanted to get in on the ground floor of importing,” Cimino says. “And at that time, China was just beginning to produce affordable leather goods. And I had very little capital to do this. We needed to start a relationship with an international bank, and Wells Fargo fit the bill. Without banking and Wells Fargo, we wouldn’t be here today.”

So the couple took a trip to a trade show in Hong Kong and began the process of building a relationship with Chinese factories, which in time developed into joint venture partnerships. Together, they created a pair of factories to produce leather goods exclusively for Canyon Outback. And although Cimino ran the retail end of the business out of the basement of his Wheaton home, he took great pains to know exactly who was doing what for him in China.

“I know all my employees in China,” he says, proudly displaying a picture of himself with his two partners in Hong Kong. “I visit them often and award all the factory workers with bonuses. What’s most important is that importing is about the relationship you have with the factory’s management and workers. If you treat them well, they will make you wonderful products with quality in mind. We think it’s very important to know everything you can about the people and about the factory itself, right down to where the exit doors are.”

While they were getting to know all of that, they were also learning how to sell their product to retails stores. They made their first sale to Eddie Bauer in 1991: a black leather backpack that still has a spot among the more recent products on the company’s “wall of fame.” But breaking into big stores and mass merchants was a challenge, especially when a recession hit.

“We were struggling to get the goods into stores,” Cimino remembers. “Then a corporation asked if we would put [heat stamp] a logo on the goods for them and we said we would find somebody who could do it.”

That unexpected introduction to promotional products changed the way Cimino looked at business. They started buying their own machinery to stamp logos and deboss products. Cimino found himself spending his time at trade shows, checking out the competition and evaluating how he could do it better. “I began to realize that promotions was a growing market,” he says. “I would walk into trade shows, look around and realize that we could do it better.”

In 1995, the company officially gave up its retail business to pursue promotional marketing clients instead. They began debossing the logos of car companies, sports teams, and major corporations onto all of their products. They took those products to trade shows, set them up in retail-like settings and started developing relationships with distributors.

“We stood out,” Cimino says. “Unlike the other leather companies, we set up a gorgeous display and showed the logos on the bags. We showed what the products would turn into.”

The Big Move

Just as the exposure at those trade shows beginning to pay off for Canyon Outback, the Ciminos began to think about getting out of Chicago. The business had long since grown out of their basement and into an expensive 1,200 sq. ft. building. The costs started adding up just as their children started growing up, and the Ciminos were ready for a change.

“Rose and I wanted to raise our children, who were 4 and 6 at the time, in New Ulm—or at least in a city smaller than Chicago,” Cimino says. “And I quickly realized that we could more effectively run our company out of southern Minnesota than Chicago.”

The family moved north, built a house on Lake Hanska and found a 1,700 sq. ft. building to lease for Canyon Outback. The move immediately cut rent in half. It also opened up the door to a whole new workforce. “Suddenly I had a higher quality labor force for what I could afford to pay hourly,” Cimino says. “And when we came here, we really tried to create jobs that people could grow into.…I have people who have been here from day one who are still here.”

When the company opened its doors in New Ulm in 1997, it was still a relatively new and unknown player in the promotional products business. Four years later, they had already outgrown their space and earned the Spirit Award, an industry honor for the fastest-growing company in the business. “By then we were absolutely sure we had made the right decision,” Cimino says. “We knew.”

The advantages of operating out of New Ulm were again apparent when Cimino began looking for land on which to build. “What New Ulm offered us, compared to Chicago, made a huge difference,” he says. “The cost of land, the cost of construction, the cost of the building itself—it was a huge difference. And between Mankato and New Ulm, we have as many resources here to run a small business as any Chicago metro area.”

Cimino hopes that the beneficial relationship has gone both ways. Although he knows Canyon Outback, with 12 full-time employees (including Cimino), six part-timers, can’t have the same kind of economic impact as a company like 3M, he works hard to make it a business good for southern Minnesota. “This company probably isn’t ever going to be the reason someone moves to New Ulm,” he says, “but I know that it is the reason at least 11 people have stayed, bought homes and raised families here. When you look at it that way, you realize that you can have an impact, even when you’re small.”

Love Of Leather

Canyon Outback has likewise had an impact on the promotional products industry. More than 250 independent representatives and 3,500-plus distributors handle the company’s products. Tiger Woods carries a Canyon Outback bag, debossed with his logo. Almost all the major car companies have ordered Canyon Outback products, from duffle bags to day planners to leather jackets. College bookstores across the country carry Canyon Outback’s line of licensed wallets, ID holders, backpacks and more—each debossed individually with the university’s own logo.

There are several reasons for the success Cimino has had with Canyon Outback. There’s the fact that he’s been able to keep prices reasonable because of his relatively low overhead. There’s the fact that he’s personally involved in the process, from the factories in China to the plant in New Ulm. But above all, there’s the sheer quality of the leather.

It’s no mystery to Cimino that his products stand apart from others. Each skin goes through a chromium salt buffing process, known to Cimino and his staff as the “butter-soft” process because of the feeling it leaves with the leather. Each skin is also drum dyed; for at least 30 days, they soak up dye in huge wood barrels. “The longer they’re in there, the softer they’ll be,” Cimino says. “Drum dying is the most expensive process for tanning skins. The dyes actually permeate the leather 100 percent, which means the leather jacket or bag will never bleed if they ever get wet.”

And that’s the answer that makes the most sense when Cimino looks back on his years in business. “After 12 years of development, it’s a lot different than it was at first,” he says. Still, some things haven’t changed. “It’s really all about the quality of the product and excellent customer service,” he says. “We’re known for gorgeous products at a reasonable price.”

Work Together, Play Together

Collage picture frames line the wall of the hallway leading to Jamie Cimino’s office. He proudly points them out during a tour, just as he did the signed Tiger Woods photo and the debossed Jaguar bag up front. “This one is from our Christmas party,” he says. “That one is from our first trip to Mexico.”’

Cimino is a big believer in treating employees well. Which is why, when the company topped $5 million in sales in 2000, he decided to close the business one Friday and take his full-time employees and spouses to Cancun for the weekend. Every year since, they’ve taken a similar trip. “Every year I set a new goal,” Cimino says. “I set it so it’s reachable and every year we’ve reached it. So we’ve gone to Cancun twice, to Mazatlan, to Las Vegas.”

It wasn’t always sun and fun for Canyon Outback. In the early days, Cimino couldn’t even provide a paid one-week vacation until after an employee had finished their two years of service. (That policy remains because many of the original employees do too.) But when the company became successful, Cimino wanted to share that with the people who helped make it happen.

Now, Cimino pays 100 percent of the health insurance costs of its full-time employees, which is very rare in today’s business arena. He throws Christmas parties for them. And he takes annual trips with all the full-time employees, save the most recent hire. “Everyone has to wait their turn,” Cimino says with a smile. “And we need someone to run the business while we’re playing around in Mexico or wherever. And they get to go the next year, because we usually hire one or two new people a year.”

“We try to create a good environment,” he adds. “I never imagined the business being so successful. But when it did become successful, we felt it was very important to keep our people here.”

Made In China

Jamie Cimino is well aware of the current controversy about American jobs being sent abroad. In many cases, he agrees with the criticisms, especially when it comes to customer service jobs being sent to foreign countries. But he sees his relationship with factories in China, where all of his leather products are produced, as something far different.

“I don’t agree with the companies who send their customer service departments overseas,” he says. “If you can’t run your business using skilled people at a fair wage in your own country, then that’s a problem. But I do believe the single largest reason we import our products is because we’ve gotten to a point in the U.S. where consumers will not pay $750 for a briefcase. And that’s what it would have to be, because it would cost that much to sew the item here.”

Besides, he knows the workings of his Chinese factories inside and out. “Our factories are family-owned businesses, which is great,” Cimino says. “Even in China, now individuals can start their own businesses with no government control.”

Cimino knows many of the almost 400 people employed in the factories personally and calls many of them friends. And he knows that his success in the United States is directly related to their success in China. “The Canyon success continues because of our company’s great work ethic and a refusal to fail over the years,” Cimino says. “My mother, who is now 71 and still running her own gift business, has been quite an inspiration. She taught me that business should be based on respect for human beings—and that is universally understood in any country and any language.”

School’s Out For Summer

When you find a fine leather bag or wallet in a college bookstore, odds are that it’s a Canyon Outback product. The New Ulm-based company is the only leather company awarded the CLC and LRG licenses. “These two organizations manage the majority of the college licensing programs in the United States,” Cimino says, “so from Minnesota State University, Mankato to Ohio State, we pretty much cover them all.”

“We were selected because of our price structure,” says Cimino, who began working with colleges and universities in 1997. “Our pricing is very affordable for the undergraduates as well as the professors. We are very popular with athletic departments, alumni associations and the greek community too.”

The prices might be a good selling tool, but Cimino knows that dollars aren’t the only driving factor for students. “One of the very chic things to have when you’re a young person in college is a leather backpack or courior bag—those are very hot right now,” he says. “It was a natural fit for us to be selling in college bookstores.”

Canyon Outback debosses the logos of schools on wallets, key chains, ID holders, and a huge variety of bags, duffles and purses. They also sell non-logo items. Cimino says a new countertop display unit, which holds seven different personalized leather products, has been a great tool for bookstores. “The bookstores love the countertop units,” Cimino says. “I’ve seen all 72 pieces of small goods sell out in one back-to-school weekend.”

© 2004 Connect Business Magazine. All Rights Reserved.